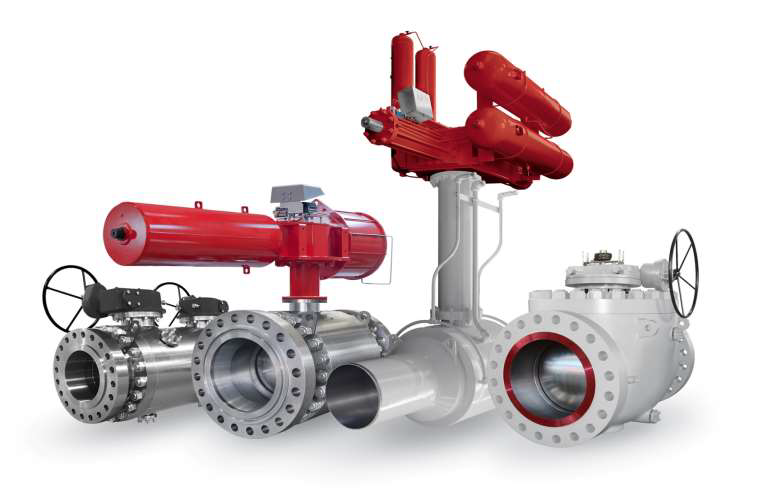

Large Bore Ball Valves

Trunnion Side Entry Split Body

- Bolted Body

- Soft / Metal Seated

- Self Relieving or Double Piston Effect Seat

- Anti Blow-Out Stem

- Double Block & Bleed

- Fire Safe API 6FA – API 607 – ISO 14097

- Antistatic Device

- Emergency Sealant Injection to Stem & Seats

- Materials in Accordance to NACE MR 01.75

- Above / Below Ground Installation

Trunnion Top Entry

- Bolted Bonnet – Cast Body / Forged Bonnet and Trim (forged body available on request)

- Soft / Metal Seated

- Self Relieving or Double Piston Effect Seat Anti

- Anti Blow-Out Stem

- Double Block & Bleed

- Fire Safe API 6FA – API 607 – ISO 14097

- Antistatic device

- Emergency sealant injection to stem & seats

- Materials in accordance to NACE MR 01.75

- Above / below ground installation

- Full in-line maintenance, either with vertical and horizontal stem

Fully Welded

- Welded Body – Cast or Forged body and closure

- Soft / Metal Seated

- Self Relieving or Double Piston Effect Seat Anti

- Anti Blow – Out stem

- Double Block & Bleed

- Fire Safe API 6FA – API 607 – ISO 14097

- Antistatic device

- Emergency sealant injection to stem & seats

- Materials in accordance to NACE MR 01.75

- Above / below ground installation

Compact

- Split body construction and DBB

- All forged construction

- Soft Seated or Metal Seated

- Self Relieving or Double Piston Effect Seat

- Anti Blow – Out stem

- Fire safe API 6FA – API 607 – BS 6755 Part.2

- Antistatic device

- Materials in accordance to NACE MR 01.75

- Short face-to-face dimension to suit special needs such as on vessels or platforms where weight and physical dimensions are critical.

Process Double Block and Bleed

- Body / Forged Bonnet and Trim

- Split Body or Top Entry

- Soft / Metal Seated

- Self Relieving or Double Piston Effect Seat

- Anti Blow – Out stem

- Fire safe API 6FA – API 607 – ISO 14097

- Antistatic device

- Materials in accordance to NACE MR 01.75

- Above / below ground installation

- Full In – Line Maintenance either with vertical and horizontal stem (when Top Entry)

Process DBB Valves Product Range

Ball Valves and Dbb Valve Construction Materials

- CARBON STEEL

- STAINLESS STEEL

- DUPLEX AND SUPERDUPLEX

- HASTELLOY

- INCOLLOY

- INCONEL

- TITANIUM

- ANY CRA CLADDING

We are ready to supply and product to suit our client’s specific requirements in all service conditions

Ball Valves and DBB Valve Seat Configuration

Self Relieving or Single Piston Effect Seat

Independent floating spring loaded seats are in contact with the ball when the pressure comes from the line to provide an affective tight seal even at low differential pressures. When there is an over pressurization into the body (due to thermal effects or leakage) one or both the seats release the overpressure into the line avoiding the body blow up.

Double Piston Effect Seat

Independent floating spring loaded seats are always in contact with the ball to provide an effective tight seal even at low differential pressures. Body cavity over pressure in this case can be released through a relief valve to atmosphere.

Upstream Seat Self Relieving and Downstream Seat Double Piston Effect

A combination of double piston effect seat on the downstream side and single piston effect on the upstream seat is available on request. This configuration maintains the sealing capacity of the valve in case of failure of the upstream seat and release of the body cavity pressure through the upstream seat.

Features and Advantages

DK-LOK® in order to comply with the latest market requirements and always looking for meeting most stringent services which are now arising in development of new fields, is now able to offer, in addition to Ball Valves for standard service, special design to suit the new challenges such as:

- SUBSEA VALVES: designed accordance with API 6DSS suitable for installation up to 5.000 meters depth. The valves are equipped with subsea actuators and or/ ROV interface to allow operation while on sea-bed.

- VERY HIGH TEMPERATURE (up to 538° C or 1000° F): developed to suit the most demanding services like: hot oil, steam, hot condensate, coke, ash, petrochemical, etc. The design foresees use of bellows to deal and energize seats, extended bonnets to allocate adjustable packing, Graphite seals and metallic bearings. Materials for surface hardening are at the forefront of the industry technology (e.g. metallic carbides, Ceramics, metallic nitrides etc.)

- CRYIOGENIC SERVICE (up to -196° C): developed to suite requirements for LNG plants and ships, the valves have special features such as stem extension for easy operation and special sealing such as KEL-F or similar.

- CLADDED VALVES: designed for sour environment and able to reduce cost impact without compromising on quality and technical performance. Cladded valves are basically supplied in lieu of solid CRA materials (Nickel Alloys such Inconel and Incolloy) manufacturing valves in Carbon Steel with a CRA weld overlay of 3mm thickness (or more in case of special requirements. )

Electrloess Nickel Plating

E.N.P is Normally Applies to Obtain:

- Wear Resistance

- Corrosion Resistance

- Low Friction

Applied Thickness:

- 0.025 mm.

- 0.050 mm.

- 0.075 mm.

- HV (64 HRC) with 520° C H.T.

- 950 HV (68 HRC) with 400° C H.T

Quality Assurance

Mechanical Tests:

- Tensile Test

- Hardness Survey

- Impact Test

- Bend Test

Other test

- Dimensional and Surface Coating

- Ultrasonic & Radiographic Inspection (UT & RT)

- Liquid Penetration Control (PT)

- Magnetic Particle Control (MP)

- Other Non-Destructive Examinations (NDT)

Special Requests

- NACE Certificate For Sour Servie

- Fire Safe Test According to API 6FA, API 607